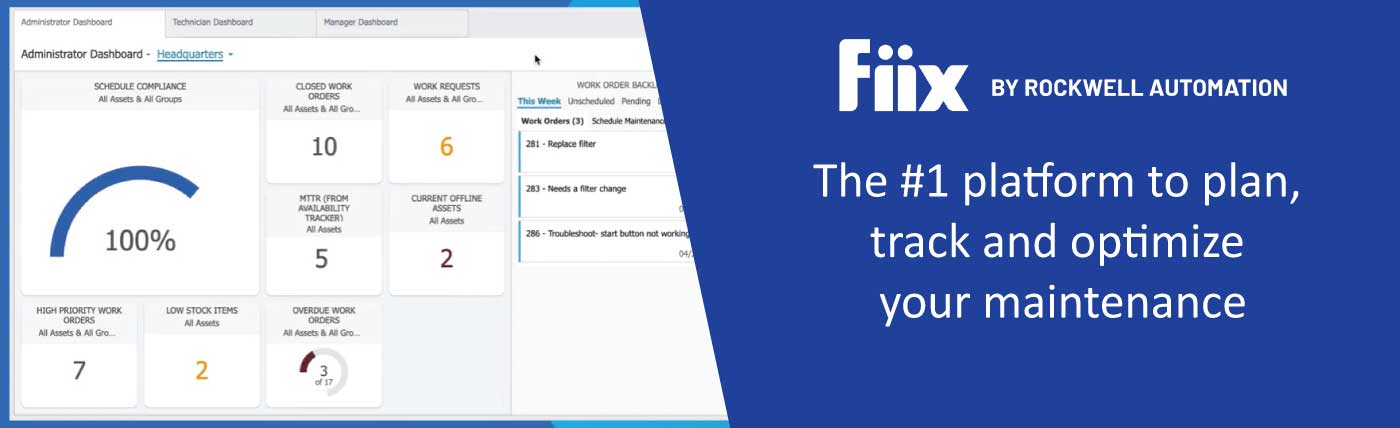

Connect teams, tools, data, and processes to get critical insights, scale your maintenance program, and boost asset performance with Fiix

Work Order Management

Asset Management

Inventory Management

Reporting & Analytics

Mobile Maintenance

With Fiix’s cloud-based CMMS software, it’s never been easier to plan, track, and optimize your maintenance

● Save money and time by optimizing your work orders, assets, parts, reports, and much more● Manage your maintenance from anywhere, at any time, with or without an internet connection, using the Fiix mobile app

● Move from a reactive to preventive maintenance approach

● Conduct audits and ensure you meet health and safety compliance

And what you can do to stop it from happening

Equipment failure happens. There’s no way to avoid it 100% of the time. The good news is, most breakdowns can be traced back to five causes and all of them can be prevented. Read about each common cause of equipment failure and what you can do to stop them.

Read the Blog: 5 Causes of Equipment Failure

Why? Get the Short Guide to Preventive Maintenance to find out

A solid preventive maintenance program can help you find equipment failure before it leads to a breakdown so you can avoid last-minute maintenance, delayed production, and overspending. Of course, putting an effective preventive maintenance program in place is easier said than done. The Short Guide to Preventive Maintenance will help you understand how to start your journey to preventive maintenance and how to use it to make your team and equipment run at their best.

Check out the eBook: The Short Guide to Preventative Maintenance

Tips for designing a program that fits your company

The best maintenance strategy is whatever keeps your assets running at their best with the fewest costs, safety risks, and disruptions. The essential guide to choosing maintenance strategies breaks down the most common approaches to maintenance so you can choose the one that helps you achieve this goal. It details how they work and when to use them to make the biggest impact on your business.

Read the Blog: The Essential Guide to Choosing a Maintenance Strategy for your Assets

Get a framework for preventive maintenance success

Before you jump into preventive maintenance, take a look at this article. It has everything you need to know about maintenance planning and scheduling. That includes aligning maintenance with company goals, improving your schedule, convincing people to give you time on equipment, and more.

Read the Blog: How to Plan and Schedule Work Orders Like the Best Maintenance Teams

Learn how to design work orders for better preventive maintenance, data and more

The average maintenance team manages over 2,000 work orders a year. This article focuses on how to design each and every one of them so you can get better data, hit business targets, and make your team’s life a lot easier in the process.

Read the Blog: A Short Guide to Building Work Orders to Achieve all Your Maintenance Goals

How to conquer your out-of-control to-do list

A runaway maintenance backlog isn’t just a long to-do list. It’s expensive, dangerous, and a disruption to everyone. That’s why this article gives you tips for avoiding deferred work and a six-step plan for reducing maintenance backlog if you already have it.

Read the Blog: A Six Step Plan for Conquering Maintenance Backlog

Get best practices for how to get the most out of your maintenance storeroom and optimize operations

It doesn’t matter how organized your maintenance schedule is if your storeroom is in chaos. Work delays and higher costs become the norm when parts are hard to find. But it doesn’t need to be this way. This article gives you a template for organizing and managing your maintenance storeroom. It covers everything from working with vendors to tracking parts usage in work orders.