At nVent HOFFMAN, we connect and protect critical controls and systems around the world while ensuring maximum productivity, and making it easy to do business with us. From selection and design tools to white papers and product catalogs, nVent HOFFMAN has the tools and expertise to make your job easier.

When health and expensive resources are involved, nVent HOFFMAN has the solutions for challenging hygienic environments

Uniquely engineered enclosures are built to withstand the high-temperature, high-pressure sprays of sanitary washdown procedures, especially for clean-in-place and harsh applications. Hygienic enclosure solutions comply with harmonized global standards that indicate how well they will prevent liquid ingress, resist corrosion, and withstand temperature and pressure ranges.

- Design principles that pass IP69, 3-A Sanitary Standards, NSF and Type 4X

- Minimize risk of bacterial growth and other contaminants

- Resist corrosion to equipment and promote longer lifecycles for controls and drives

- Speed and simplify routine maintenance for sanitary washdown procedures

Learn more about::

Redefine Simplicity When Ordering and Assembling

nVent HOFFMAN’s comprehensive Global IEC rated standard product range includes mild steel and stainless steel floor stand, wall mount and terminal box enclosure solutions. Accelerate the specification and installation process through interchangeable accessories and tool-free assembly, while streamlining ordering with a single global part number.

Learn More About:

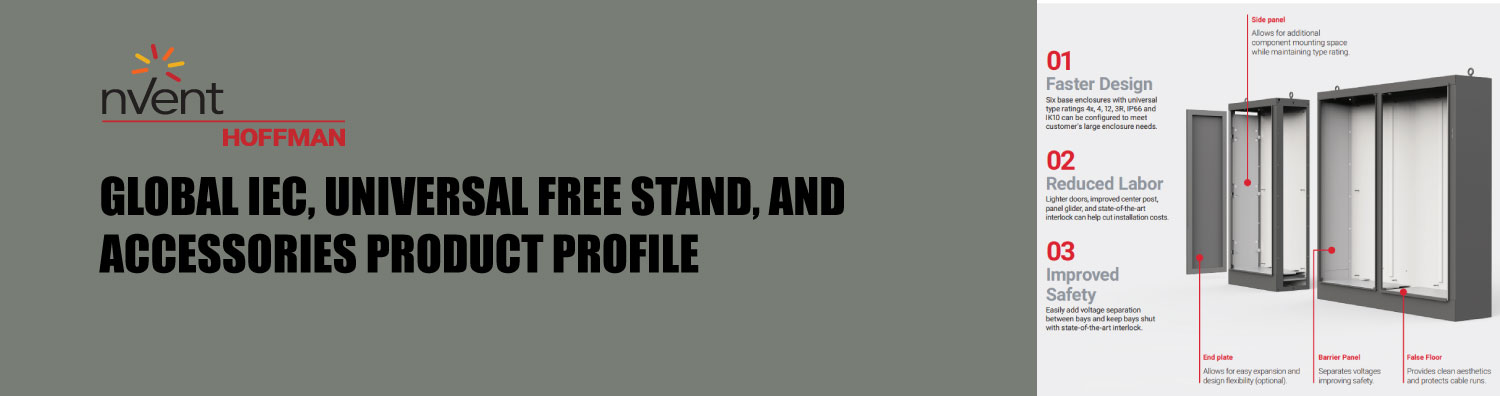

Get to Your Next Project Faster

Designed for flexibility, the nVent HOFFMAN Universal Free-Stand portfolio enables panel builders and integrators to start with simplified base enclosures and customize with accessories and modifications as needed. The portfolio is robust, bayable, and has multiple type ratings with accessories focused on safety and component mounting density to enable faster design, modification, and assembly, while improving control panel safety.

Learn More About:

Universal Free Stand Enclosures

ModCenter: Precision automation for holes and cutouts reduces lead times and improves the bottom line

- Modification equipment for panel builders enables fast modification of stocked items for quick shipping

- Fast machining of various materials including: mild steel, stainless steel, copper, aluminum, fiberglass and thermoplastics

- Shorter lead times for customers and lower costs for panel builders

Personal Wiring Assistant PWA2000

The Personal Wiring Assistant, PWA2000 revolutionizes wiring productivity at your facility. Compared to traditional wiring methods, the Personal Wiring Assistant delivers the right wire, when you need it, in a fraction of the time. Instead of workers spending hours prepping wire for installation, automated wire prep can now be done at the same time as install, saving time and money.